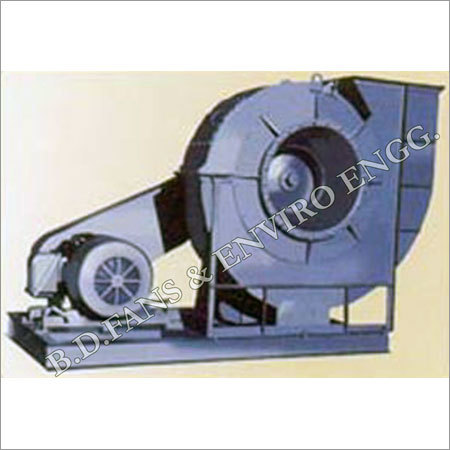

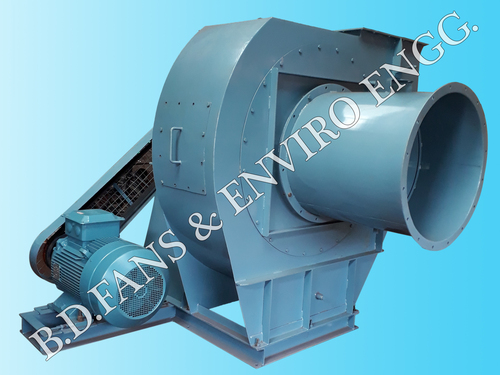

Centrifugal Fan

Centrifugal Fan Specification

- Max Pressure

- 85 mmWG

- Life Span

- 8-10 Years

- Power

- 1.1 kW

- Motor Power

- 1.5 HP

- Output Power

- 1.1 kW

- Pressure Range

- 50-85 mmWG

- Flow Rate

- 800 m/hr

- Product Type

- Centrifugal Fan

- Material

- Mild Steel

- Capacity

- 800 m/hr

- Pressure

- 60 mmWG

- Application

- Industrial ventilation, Air handling unit

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 1440 RPM

- Noise Level

- 65 dB

- Power Source

- Electric

- Voltage

- 380 V

- Weight

- 32 kg

- Dimension (L*W*H)

- 600 x 400 x 450 mm

- Color

- Green

About Centrifugal Fan

Centrifugal FanCapacity from 500m3/hr. to 10,00,000m3/hr. at a static pressure from 30mmwg to 3000mmwg and temperature up to 750oC.

- Single width and double width type model available.

- These centrifugal fans / blowers are available in MS / SS / AL construction with FRP lined and hard faced.

- Air Pollution Control system

- Ventilation system

- Dust / fume extraction system

- Evaporative cooling system and much more .

Product details

|

Max Capacity |

500 -12,00,000 m3/hr |

|

Temperature |

Up to 550 deg C |

|

Brand |

B. D. Fans And Enviro Engineering |

|

Frequency |

50-60 Hz |

|

Phase |

3 Phase |

|

Voltage |

440V |

|

Efficiency |

90 % |

|

Blower Type |

Duct Mounted Fan |

|

Pressure |

20-3000 mm WG |

|

Fan Speed |

700 to 2900 RPM |

|

Usage/Application |

Industrial |

|

Motor Power |

0.5 HP to 400HP |

Efficient Industrial Air Handling

Designed for industrial ventilation and air handling units, this centrifugal fan offers a forward-curved, 8-blade impeller powered by a robust 1.5 HP motor. It delivers consistent airflow and reliable pressure in diverse manufacturing and processing environments, with a mounting base for ease of installation.

Durable Design & Long Service

Built from mild steel with a protective green powder coating, this fan boasts an IP54 protection class, ensuring resistance against dust and splashes. Double-sealed ball bearings and Class F insulation enhance motor durability, supporting continuous operation with minimal maintenance.

Energy-Efficient and Safe Operation

Operating at 380V, 1.1 kW output power, and 50 Hz frequency, this centrifugal fan is energy-efficient while maintaining a low noise level of 65 dB. The direct drive and efficient impeller design help optimize power usage for extensive industrial use, all while ensuring safety and compliance.

FAQs of Centrifugal Fan:

Q: How is this centrifugal fan installed in an industrial setting?

A: The fan features a base-mounted design for stable and straightforward installation on flat surfaces, making it suitable for integration with air handling units or direct placement within industrial ventilation systems.Q: What applications are best suited for this centrifugal fan model?

A: With its robust airflow and durable construction, this centrifugal fan is ideal for various industrial ventilation tasks, air handling units, and any facility requiring consistent medium-pressure air movement.Q: When should the bearings or motor be serviced?

A: The double-sealed ball bearings are designed for long life and minimal maintenance, but its recommended to inspect them along with the motor annually to ensure optimal performance and extend the equipments lifespan.Q: Where can the fan operate in terms of environmental conditions?

A: This model operates reliably in ambient temperatures ranging from -10C to 60C, with an IP54 protection class guarding against dust and water splashes, suitable for many industrial environments across India.Q: What is the process for ensuring safe and efficient operation of the fan?

A: Ensure the fan is correctly installed on a secure base, verify electrical connections comply with the 380 V, 50 Hz requirement, and check that obstructions are cleared from the 250 mm inlet and 140 mm outlet before operation.Q: What are the usage benefits of the direct drive and forward-curved impeller design?

A: Direct drive minimizes transmission losses and reduces maintenance, while the forward-curved impeller improves airflow efficiency and operates at lower noise levels, making this fan a cost-effective solution for continuous industrial use.Q: How does this fan benefit industrial users in the long term?

A: With a lifespan of 810 years and low noise operation (65 dB), the fan offers reliable ventilation, reduced downtime from maintenance, and energy efficiency, contributing to a sustained productive environment for industrial operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Centrifugal Blower Category

Centrifugal Blower

Material : other , Mild Steel or Stainless Steel

Product Type : Centrifugal Blower

Power Source : Other, Electric

Application : Industrial ventilation and air movement, Other

De Dusting Id Fan

Price 100000 INR / Unit

Minimum Order Quantity : 1 Gross

Material : other , Metal (Likely Steel)

Product Type : Others, Dedusting ID Fan

Power Source : Other, Electrical

Application : Other

Coupling Drive Centrifugal Fan

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Steel

Product Type : Centrifugal Blower

Power Source : Electric Blower

Centrifugal Fan Impeller

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Steel

Product Type : Centrifugal Blower

|

B.D. FANS & ENVIRO ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |